Since February, the NiceLab association (“Laboratory”) has opened a small workshop in Nice. It houses a 3D printer, made by Marc Ferner, the association’s president, along with Bertrand, the association’s treasurer.

The association aims to promote the gathering of people with different skills to develop the city of Nice technologically.

“It’s important to know that the 3D printer is a French invention that already existed 30 years ago. Three years ago, the patent entered the public domain. Some were then able to make modifications, gradually improve it, and also produce hundreds of models, resold for 30,000 to 50,000 euros. The patent is a real hindrance to innovation. The 3D printer is a typical example of this. We witnessed the rise of its development when it became collective,” recounts Marc Ferner.

This idea of collectivity and sharing is advocated by the president of the association. “We want to combine technical and social aspects. The goal of the association is to practice open material, which means allowing the public to bring their knowledge to propose improvements to the 3D printer or to remake certain things. In fact, for now, the 3D printer we have built needs some adjustments. Precisely, we are working on its improvement,” explains the president of the association and volunteer.

Once functional, NiceLab will open its doors to users who need to manufacture a given object, implementing a subscription system to finance various expenses. But before that, training is necessary. “We should first train future users in the use of the software, in prototyping. It requires a lot of precision because it is customized,” emphasizes the association president.

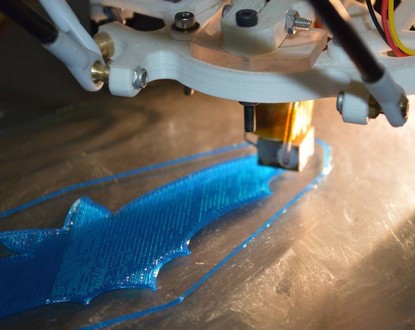

The 3D printer is actually connected to a computer on which software is installed to build the prototype of the desired object. Then, a biodegradable resin, derived from corn starch, is melted by a heating head that deposits plastic on the support, thus manufacturing the object.

For now, manufacturing an object measuring six centimeters takes three hours. The size and complexity of the desired object determine the time required for its fabrication. “In addition to increasing the speed of this printer, we are working on the creation of a second, more precise 3D printer. We also wish to produce a digital milling machine to cut wood or machine all types of metal parts, as well as a circuit engraver,” states Marc Ferner.

“In a place like ours, only eight people can work at a time. Our goal would be to stay open all day, expand, and have more equipment to offer people. That’s why we are trying to find a larger space,” concludes the volunteer.