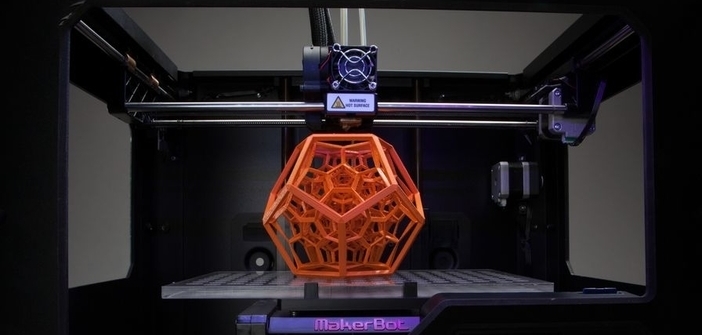

For several years, 3D printers have revolutionized multiple fields. They make certain manufacturing processes considered too costly more accessible. To do this, it’s necessary to understand and master them.

Democratized since the 2010s, a lot of progress has been made since then. To recall, the first 3D printer was invented in 1987 by Chuck Hull.

Simplified and more artisanal processes for professionals

Until the early 2000s, few had one. They were mainly used for industrial prototyping. Nowadays, it has evolved to become more effective and more efficient. This rapid prototyping allows users to create a 3D model. Today, it is simpler to use 3D printers. They are used to make low-cost parts. The geometric shapes and materials are generally basic. The quantities are limited and dimensions more approximate. The rapid machining phase of a product in 3D printing is essential. It is unique and differs from classic industrial machining phases.

Diverse and varied applications

These parts can be used to construct medical devices and custom-made artificial prostheses, referred to as bio-printing. Doctors can thus reproduce living cells such as bones, cartilage, or even skin. Eventually, researchers will be able to reproduce entire organs identically. Apart from that, the interest is also in being able to create models. They will be able to better perceive the patient’s specifics. They can help prevent medical errors. Surgeons will be thus trained more easily. They will practice on life-size models without risks.

Specific materials used

The main material is plastic. Moreover, plastic injection is one of the most commonly used techniques. It has the advantage of having multiple physical properties. This facilitates alloying. We then talk about thermoplastics (via FDM or SLS processes) or thermosets. Metals are also favored. For example, titanium can be cited.